Understanding DIN Rail Power Meters: Core Functionality and Benefits

DIN rail power meters represent a critical component in modern energy management systems, offering precise measurement capabilities in a compact, standardized form factor. These devices mount seamlessly on standard 35mm DIN rails - the universal mounting system used in electrical enclosures worldwide - making them ideal for panel builders and system integrators.

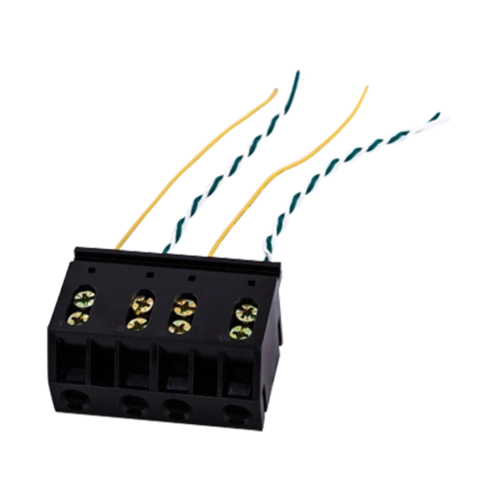

Dac2102 DIN Rail Single Phase Intelligent AC Power Meter

1.1 Fundamental Operating Principles

At their core, DIN rail power meters function by continuously sampling voltage and current waveforms to calculate various electrical parameters. The measurement methodology typically involves:

- Voltage sensing through direct connection or potential transformers

- Current measurement via CTs (current transformers) or Rogowski coils

- High-speed analog-to-digital conversion (typically 16-bit or higher)

- Digital signal processing for parameter calculations

- Data presentation through displays or communication interfaces

Advanced models employ sophisticated algorithms to analyze waveform distortions, providing insights into power quality issues that conventional meters might miss. For instance, while basic models might simply measure RMS voltage, premium DIN rail mounted energy meters can perform Fourier analysis to quantify harmonic distortion up to the 50th harmonic.

1.2 Key Advantages Over Traditional Metering Solutions

Compared to conventional panel meters or standalone energy meters, DIN rail mounted solutions offer several distinct benefits:

| Feature | DIN Rail Meter | Traditional Meter |

|---|---|---|

| Installation Time | Seconds (tool-less mounting) | Minutes (screw mounting) |

| Space Requirements | Compact (typically 1-4 modules) | Bulkier enclosures |

| Scalability | Easy expansion on rail | Limited by enclosure |

| Maintenance | Simple replacement | Wiring disconnection required |

| Standardization | Universal rail compatibility | Vendor-specific mounts |

Comprehensive Applications Across Industries

The versatility of DIN rail energy monitoring devices enables their deployment across diverse sectors, each with unique requirements and implementation approaches.

2.1 Industrial Manufacturing Environments

In heavy industrial settings, these meters perform critical functions:

- Machine-level monitoring: Tracking energy consumption of individual CNC machines, presses, or robotic cells to identify inefficient equipment

- Production line balancing: Comparing energy usage across parallel production lines to optimize load distribution

- Demand charge management: Preventing peak demand penalties by monitoring real-time power draw

- Predictive maintenance: Detecting abnormal power patterns that indicate impending motor or bearing failures

A typical automotive plant might deploy hundreds of digital DIN rail power meters throughout its facility, creating a comprehensive energy monitoring network that feeds data to centralized SCADA systems.

2.2 Commercial Building Implementations

Modern building automation systems increasingly rely on distributed metering solutions:

- Tenant submetering: Allocating energy costs accurately in multi-tenant office buildings

- HVAC optimization: Monitoring chiller, pump, and fan energy usage to identify savings opportunities

- Lighting control integration: Providing consumption data to daylight harvesting systems

- LEED certification support: Documenting energy performance for green building certifications

Technical Selection Criteria for Optimal Performance

Choosing the right DIN rail electrical measurement devices requires careful evaluation of numerous technical specifications and application requirements.

3.1 Accuracy Class Considerations

Measurement accuracy varies significantly across meter classes:

| Class | Active Energy | Reactive Energy | Voltage | Current | Typical Applications |

|---|---|---|---|---|---|

| Class 0.5S | ±0.5% | ±1% | ±0.5% | ±0.5% | Utility metering, high-value processes |

| Class 1 | ±1% | ±2% | ±1% | ±1% | Most industrial applications |

| Class 2 | ±2% | ±3% | ±2% | ±2% | Basic monitoring, cost allocation |

3.2 Communication Protocol Options

Modern DIN rail power analyzers support various protocols, each with distinct advantages:

- Modbus RTU: The industrial standard for serial communication (RS-485)

- Modbus TCP: Ethernet-based implementation for network integration

- BACnet: Preferred in building automation systems

- M-Bus: Common in European energy metering applications

- Wireless options: LoRaWAN, Zigbee for hard-to-wire locations

Advanced Installation Techniques and Best Practices

Proper implementation of DIN rail metering solutions requires attention to both electrical and mechanical considerations.

4.1 Comprehensive Wiring Guidelines

Correct wiring ensures both safety and measurement accuracy:

- Voltage connections: Use appropriately rated conductors (typically 1.5mm² for signals)

- CT installations: Ensure proper orientation and never open-circuit secondary windings

- Grounding: Implement single-point grounding to avoid measurement loops

- Separation: Maintain minimum 10mm clearance between voltage and current circuits

- Labeling: Clearly mark all conductors at both ends using permanent markers

4.2 Environmental Considerations

While DIN rail meters are designed for harsh environments, certain precautions apply:

- Temperature: Most units operate from -25°C to +60°C ambient

- Humidity: Typically 95% RH non-condensing maximum

- Altitude: Derate above 2000m elevation

- Vibration: Secure wiring in high-vibration areas

- EMI: Use shielded cables near variable frequency drives

Future Trends in DIN Rail Metering Technology

The evolution of DIN rail energy monitoring devices continues to accelerate, driven by emerging technologies.

5.1 IoT and Cloud Integration

Next-generation meters incorporate:

- Embedded cellular modems for standalone connectivity

- Edge computing capabilities for local data processing

- Blockchain-compatible architectures for energy trading

- API interfaces for custom application integration

5.2 Advanced Power Quality Monitoring

Cutting-edge features now include:

- Transient capture (microsecond resolution)

- Flicker measurement per IEC 61000-4-15

- Unbalance monitoring with phase angle tracking

- Predictive analytics for equipment failure

These advancements position DIN rail power analyzers as central components in smart grid and Industry 4.0 implementations, far beyond their original metering purposes.

English

English 中文简体

中文简体