Collaborative Applications with Panel Power Meters and Current Transformers

In the fields of industrial automation and energy management, selecting the right power monitoring equipment is crucial. The DIN Rail Power Meter, known for its easy installation and comprehensive functionality, is widely favored, especially in applications such as distribution cabinets and industrial control systems.

Dac4120c DIN Rail Single Phase AC WiFi with Relay Power Meter

1. Core Advantages of DIN Rail Power Meters

A DIN Rail Power Meter is a power monitoring device mounted directly on standard DIN rails (35mm), offering the following benefits:

Easy Installation: No additional fixing required, saving space and ideal for dense electrical environments.

Multi-Function Monitoring: Measures voltage, current, power, energy, power factor, and more.

Rich Communication Interfaces: Typically equipped with RS-485, Modbus, Profibus, etc., for seamless integration into SCADA or energy management systems.

High Accuracy: Typical accuracy of 0.5% to 1%, meeting industrial-grade requirements.

Typical Applications:

Power monitoring in industrial production lines

Energy management in smart buildings

Photovoltaic power generation systems

2. DIN Rail Power Meter vs. Panel Power Meter

Panel Power Meters are typically embedded in switchboard panels, making them suitable for applications requiring direct readings. Below is a comparison:

| Parameter | DIN Rail Power Meter | Panel Power Meter |

|---|---|---|

| Installation | DIN rail mounting | Panel-embedded mounting |

| Application | Industrial control cabinets, dense power distribution | Switch rooms, scenarios requiring direct readings |

| Communication | Supports multiple protocols (Modbus, RS-485, etc.) | Some models only support local display |

| Expandability | Easy to expand with additional modules | Fixed installation, limited expandability |

| Typical Accuracy | 0.5% - 1% | 0.5% - 2% |

Selection Advice:

For remote monitoring or system integration, prioritize DIN Rail models.

For on-site visual readings, Panel models are more suitable.

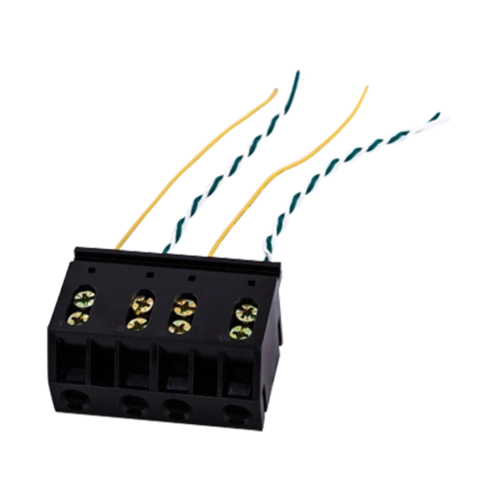

3. Role of Current Transformers (CTs) and Collaborative Applications

Current Transformers (CTs) are critical components in power monitoring systems, converting high currents into measurable low-current signals (typically 5A or 1A) for safe meter readings.

Synergy with DIN Rail Power Meters:

High-Current Scenarios: When line currents exceed the meter’s direct range (e.g., above 100A), CTs are required.

Flexible Configuration: CT ratios (e.g., 100:5) can adapt to different current levels, extending the meter’s measurement range.

Key Considerations:

CT accuracy should match the meter (e.g., 0.5-class CT + 0.5-class meter).

Ensure CT secondary circuits are never open during installation to avoid high-voltage hazards.

4. How to Choose a Power Monitoring Solution?

DIN Rail Power Meter: Best for modular, remote-monitoring industrial applications.

Panel Power Meter: Ideal for fixed installations requiring local display.

Current Transformer: Essential for high-current systems, ensuring safety and accuracy when paired with meters.

By combining these three devices effectively, comprehensive power monitoring—from low-voltage distribution to high-voltage systems—can be achieved, enhancing energy efficiency and fault prevention.

English

English 中文简体

中文简体